Dark-colored synthetics are great; absolutely on light colours too. Cottons look terrific in any shade — even low cost cotton shirts look good! So, if you need to get a 500-piece order out and solely have one heat press, you presumably can estimate about 30 seconds per shirt software time. DTF does not beat a professional £13,000 – £250,000+ DTG printer. I’d recommend DTF for small print retailers and high end DTG for established businesses printing 100+ t-shirts per day.

Screen printing is very suitable for giant orders as value efficiency increases as orders improve; the extra orders acquired, the decrease the unit prices. This is detrimental for small orders as printing small quantities is less cost-effective due to the time, labor, and preparation required to print a batch. If you’re able to get began together with your printing business, you’ll need equipment and provides.

Once printing has completed, rigorously raise the printed DTF Xpress switch film. Thankfully, we now offer DTF printing which is considerably more price effective than DTG Printing as a outcome of it does not require pretreatment, it uses so much less ink. DTF printers most likely produce the softest feel/hand of any transfer technology.

DTG definitely has that gentle hand that folks talk about, however we predict they’re quite similar texture-wise to DTF prints. If anything, we imagine that DTF printing is starting to catch up. Screen printing handles bulk orders very nicely as a end result of increasing cost-effectiveness for larger orders; the more orders you obtain, the extra affordable your unit costs become. This works in opposition to its favor the place small orders are involved, as it becomes much less cost-effective to print small portions with the period of time, labor, and preparation wanted to print a batch. If after peeling the movie there is some leftover powder on the perimeter of the design, repress the design for additional seconds, so it can melt away. A complete guide on tips on how to successfully use the Direct-to-Film printing approach.

Otherwise, you might end up with imperfect prints or much less vibrant inks. Automating pretreatment will set your price range again significantly. Direct-to-garment printing is digital printing onto a garment, the identical way you’d usually print a document on your desktop printer. You’ll first have to digitize a design into the system, then a raster image processor software interprets it into a set of directions the printer can use to print it out. The understanding of the two turns into the first difference between DTF vs DTG. Here we offer additional differences between the two printing strategies using this digital printing.

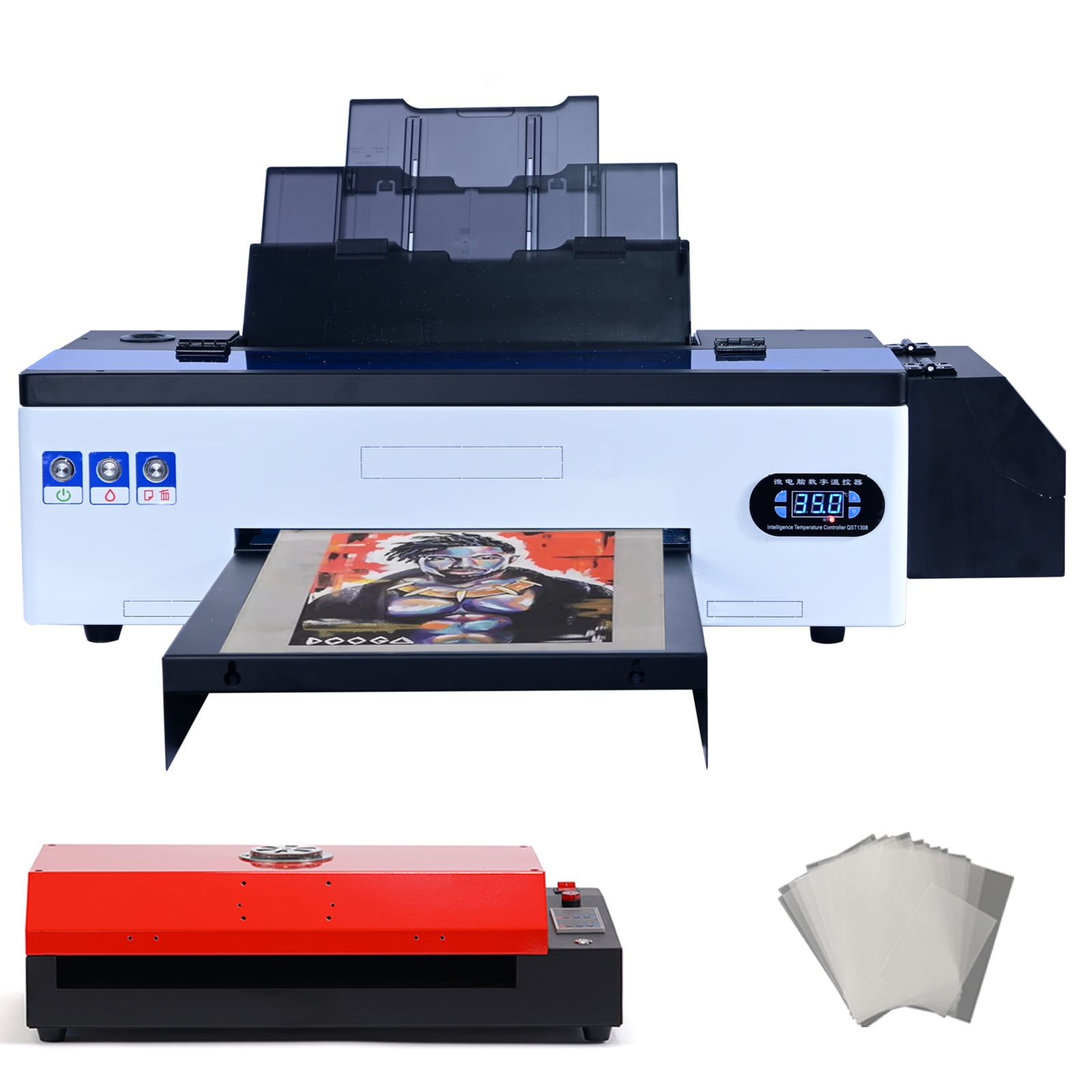

It won't look like a lot but when it can save you 5 minutes per shirt that’s a lot of saved time per day. In https://www.bonestudio.net/ of DTF equipment, you’ll solely need a DTF printer, inks, transfer films, and a warmth press. You can easily purchase a reasonable converted desktop printer, a heat press, and different essential items with a relatively frugal budget. Most importantly, you won’t need a pre-treatment machine or resolution, additional driving down your expenses.